Inishmeane

All photos (c) 2016 The Fibre Co. & Tommy Martin

Early this past summer I got a ping from Carmen at A Yarn Story saying "Have you seen this new Fibre Company yarn Arranmore? It's luscious and glorious and I want a men's sweater design for it!" Before I knew what had hit me we were looking at a Pinterest board and discussing constructions and yarn colours and motifs. We debated henley style versus gansey, raglan versus set in sleeve...the possibilities were endless!

Most importantly, we wanted to come up with a men's sweater that would appeal both to men and the knitters who knit for them. The stereotype is that men want plain, boring, miles-of-stockinette navy or black or brown or dark green pullovers. That's it. But honestly, who among us wants to knit that? I can envision a scenario in which my brain was so fried that I would be good for nothing but plain stockinette in the round, but the prospect is just a bit too blah to be appealing for very long.

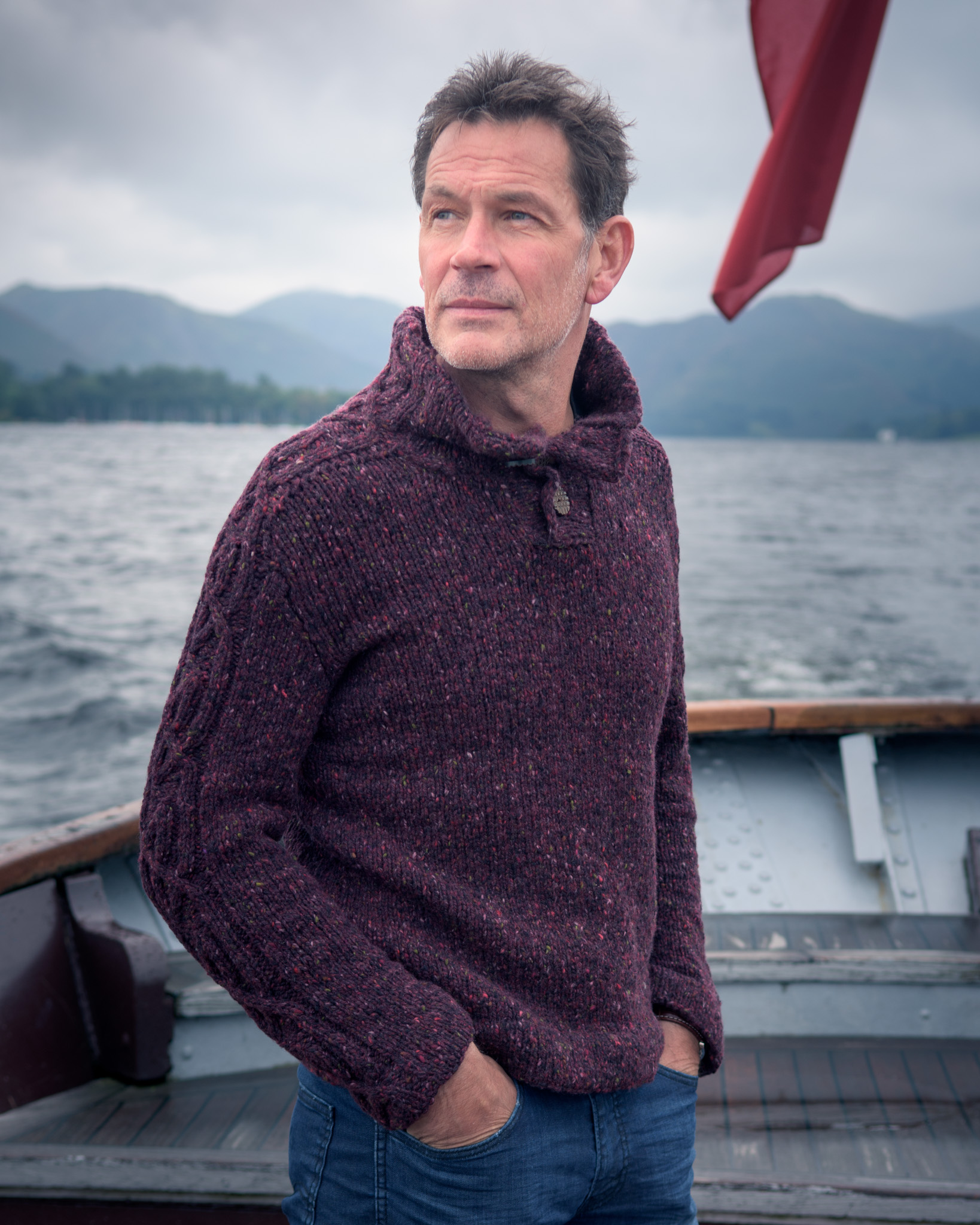

So we decide on a mostly stockinette sweater (to cover the standard insistence on "plain") which would highlight the tweedy rustic nature of the yarn, but with some interesting details to keep the knitter of said sweater from going nuts in a sea of blank canvas. A couple of serious cables for example, and a saddle shoulder construction. A tall collar and a henley neckline. A cozy sweater in a glorious Aran yarn that wraps around you like a big hug.

Then there was swatching and knitting (in the ludicrous heat that was Washington DC this past summer when we were there) and a frantic round of button choosing, and some pattern writing. And now, Carmen and I are thrilled to present Inishmeane, named for a small island off the coast of County Donegal.

A dog almost as cute as The Wee Ridiculous Dog that lives in my house

Worked in seven sizes (finished chest measurement from 96.5-157.5 cm/38-62"), Inishmeane is worked in the round from the bottom up, starting with a turned hem. The body is worked in the round to the underarms, and then the front and back are worked flat. Sleeves are worked (also with a turned hem) with a mirrored cable panel on each, and then the cable continues across the shoulder, getting attached to the front and back as you work. Then the collar is worked flat, with the cables continuing on either side, and the front button bands are picked up and worked flat.

I am super thrilled with how this sweater has come out, but it wouldn't have happened without the support of a lot of people: first off, Carmen, who asked me to come up with something for her, and was an absolute pleasure to work with from start to finish (let me know when the next one needs to come through, ok?), my lovely tech editor Deb for her eagle eyes (!), Daphne and Ian at The Fibre Company for yarn support and being generally all around some of the most lovely people it's been my pleasure to meet in this industry, and Tommy Martin who takes unbelievably phenomenal pictures of knitwear in the Lake District (as evidenced by these photos and the gorgeous shoot he did for Nordlándda last year).

The pattern is available now from Ravelry and from A Yarn Story directly, along with oodles and oodles of gorgeous Arranmore. I'm already contemplating what colour to pick for my, I mean Alex's Inishmeane! And you can read more about the process from Carmen's side of the story on her blog.